Introduction

Mass production is a manufacturing system in which large volume of goods are produced by using efficient technology and automation. In this process system large amount of standardized products are manufactured that helps to minimize the production costs and achieve economies of scale. In this post we are going to discuss major benefits and drawbacks of mass production system.

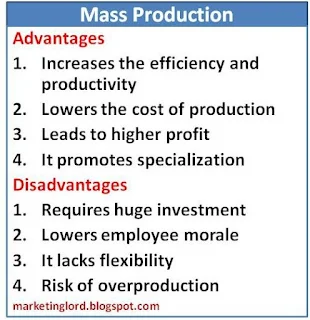

Advantages Of Mass Production

The main advantages of mass production are as follows:

1. Increased Efficiency And Productivity

Because of automated technology and strict monitoring this manufacturing system increases the production rate. Therefore, large volume of products can be produced at a fast pace. So, mass production improves efficiency and productivity of the firm.

2. Lower Cost Of Production

Firms can produce large quantity of goods faster by using modern machines and optimizing the production process with fewer employees. So, it lowers the cost of production and leads to economies of scale. Therefore, it is cost saving production process.

3. Higher Profit

As we know that mass production helps to increase the rate of production and decreases the cost of production, it leads to increase in the earnings of the producers.

4. Lower Selling Price

Because of lower per unit cost of production, a firm can sell its products at lower price than its competitors in the market. It attracts more customers and encourages them to buy the product. So, it helps to increase sales and expand the market share.

5. Specialization

Another notable advantage of mass production is that it promotes specialization. It hires specialists and experts to handle modern machines. It also provides training and conducts skill development programs to increase the efficiency and performance of employees.

6. Uniform Quality

Modern production technology, effective monitoring and strict supervision minimizes the chance of error and mistake while producing the goods. So, mass production ensures the uniform quality of product produced by the firm.

Disadvantages Of Mass Production

The main disadvantages of mass production process are as follows:

1. Capital-intensive System

Mass production requires huge initial investment for factory setup. It requires a lot of capital to acquire fixed assets such as plant, machinery and materials. So, small producers cannot afford this system.

2. Lack Of Flexibility

Another drawback of mass production is that it is inflexible system. Plant, machines and devices are arranged to perform a specific task. It is very difficult to make any changes or restructure the layout.

3. Decreased Employee Morale

Mass production may demotivate employees because of repetitive nature of job. It decreases the employee morale that may lead to increase labor turnover rate.

Also Read

Advantages and disadvantages of continuous production

Advantages and disadvantages of job production

4. Lower Product Quality

Mass production gives more emphasize on the volume of output. Its main objective is to produce large quantity of goods in short period of time. It may decrease the quality of output.

Pros And Cons Of Mass Production In Brief

Pros

* It saves production time and cost

* It increases the rate of production and minimizes the cost of production

* Helps the firm to achieve economies of scale

* It provides competitive advantage

* It ensures uniform product quality

Cons

* It is cost and resource consuming system

* It is inflexible and difficult to restructure

* Employees may feel monotonous and demotivated

* It is not suitable for small companies

* High possibility of overproduction