What Is Continuous Production ?

Continuous production (also known as flow production) refers to non-stop manufacturing of products on continuous basis. It is uninterrupted process which is designed to produce large quantity of standardized products in a continuous flow.

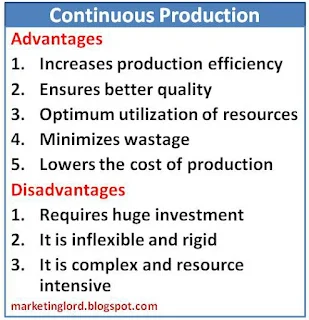

Advantages Of Continuous Production System

The main advantages of continuous production are as follows:

1. Greater Production Efficiency

Because of automation and optimized manufacturing process it leads to increase the rate of production.

2. Uniform Quality

Another notable benefit of continuous production system is that it ensures uniform and consistent quality of output. Because of advanced technology, real time monitoring and proper adjustments it lowers the possibility of errors that helps to produce identical and better quality products.

3. Maximum Utilization Of Resources

This production system promotes proper utilization of resources in order to increase the output. Resources such as men, money and materials should be effectively utilized to ensure continuous flow of manufacturing process.

4. Wastage Minimization

Because of automation, better utilization of resources and proper monitoring it minimizes the wastage materials and lowers unwanted costs.

5. Cost Efficiency

Continuous production adopts latest and highly optimized technology and automation system to produce goods. So, it increases the volume of output and minimizes wastage that decreases the cost of production.

6. Economies Of Scale

Because of high quantity of production and decreased cost of production, producers can enjoy the benefit of economies of scale.

7. Suitable For

Continuous production is suitable for large manufacturing companies that require mass production of standardized goods.

Disadvantages Of Continuous Production System

The main disadvantages of continuous production can be described as follows:

1. Complex System

It is complex and resource intensive production system. It is very difficult to set up and operate because of complexity.

2. Huge Initial Investment

Continuous production requires huge initial investment to acquire production plant and machinery. So, small firms cannot afford this system.

3. Unsuitable For

It produces identical goods in large quantity. But it is not suitable to produce different types of products in small quantity.

4. Lacks Flexibility

Another drawback of continuous production is that it is inflexible system. It cannot be changed or customized easily because of rigidity.

Also Read

Advantages and disadvantages of mass production

Advantages and disadvantages of job production

5. Possibility Of Interruption

In this system, all the stages of production are dependent to each others. So, whole process will be interrupted in case of any breakdown in any process or stage of production.

Pros And Cons Of Continuous Production In Short

Pros

* It ensures better quality of output

* It increases the production efficiency

* It decreases the production costs that leads to increase profit

* It minimizes the labor costs by adopting automation

* It saves time and energy by using modern production technology

Cons

* It requires large capital

* It is complex and inflexible system

* One small fault may interrupt the whole production process

* It is not suitable for small firms.